- PRODUCTS

OUR PRODUCTS

- WINDOWS

Fixed Window

Casement Window

Awning Window

Bi-Fold Window

Sliding Window

Pivot Window

- SWING

Single Swing

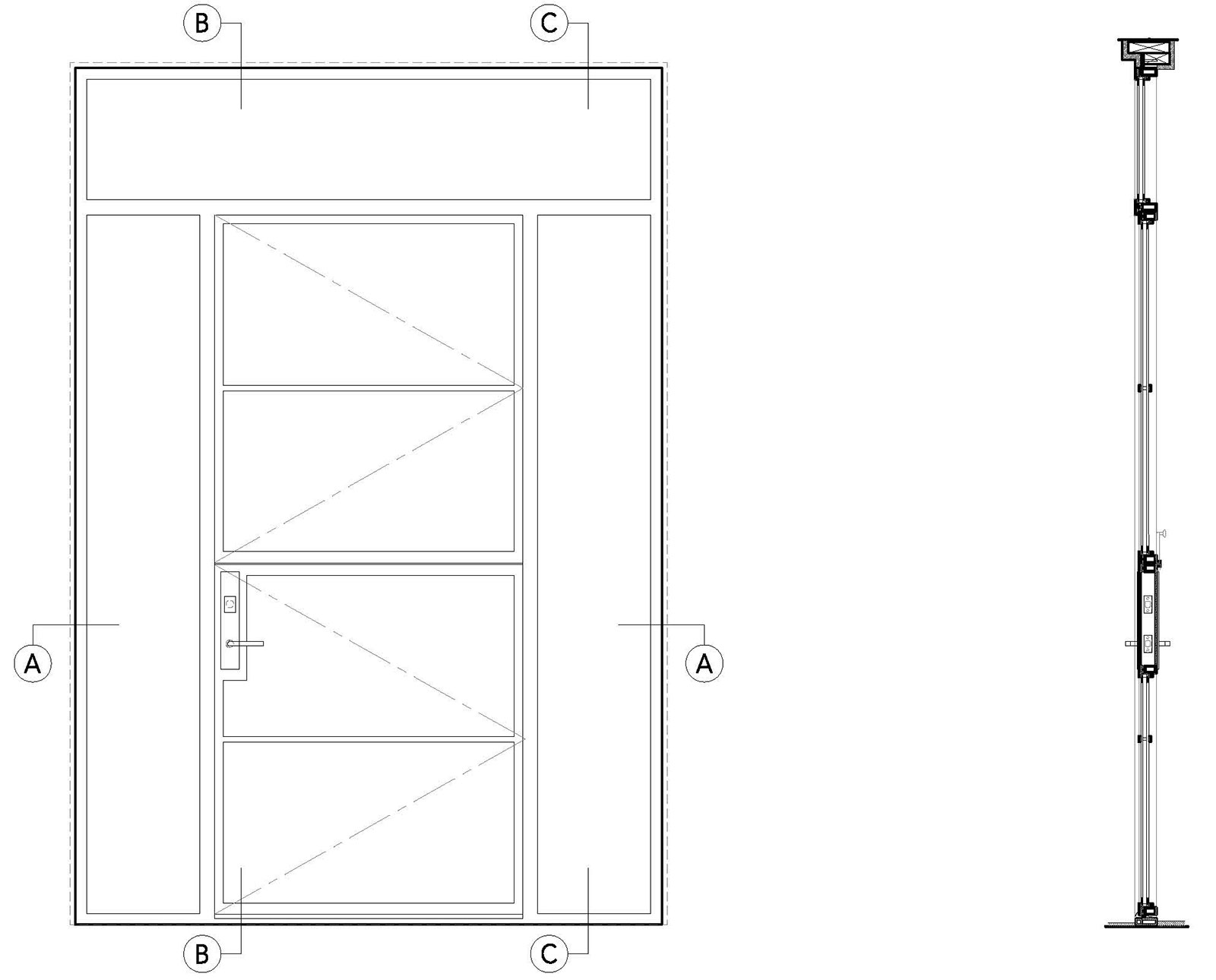

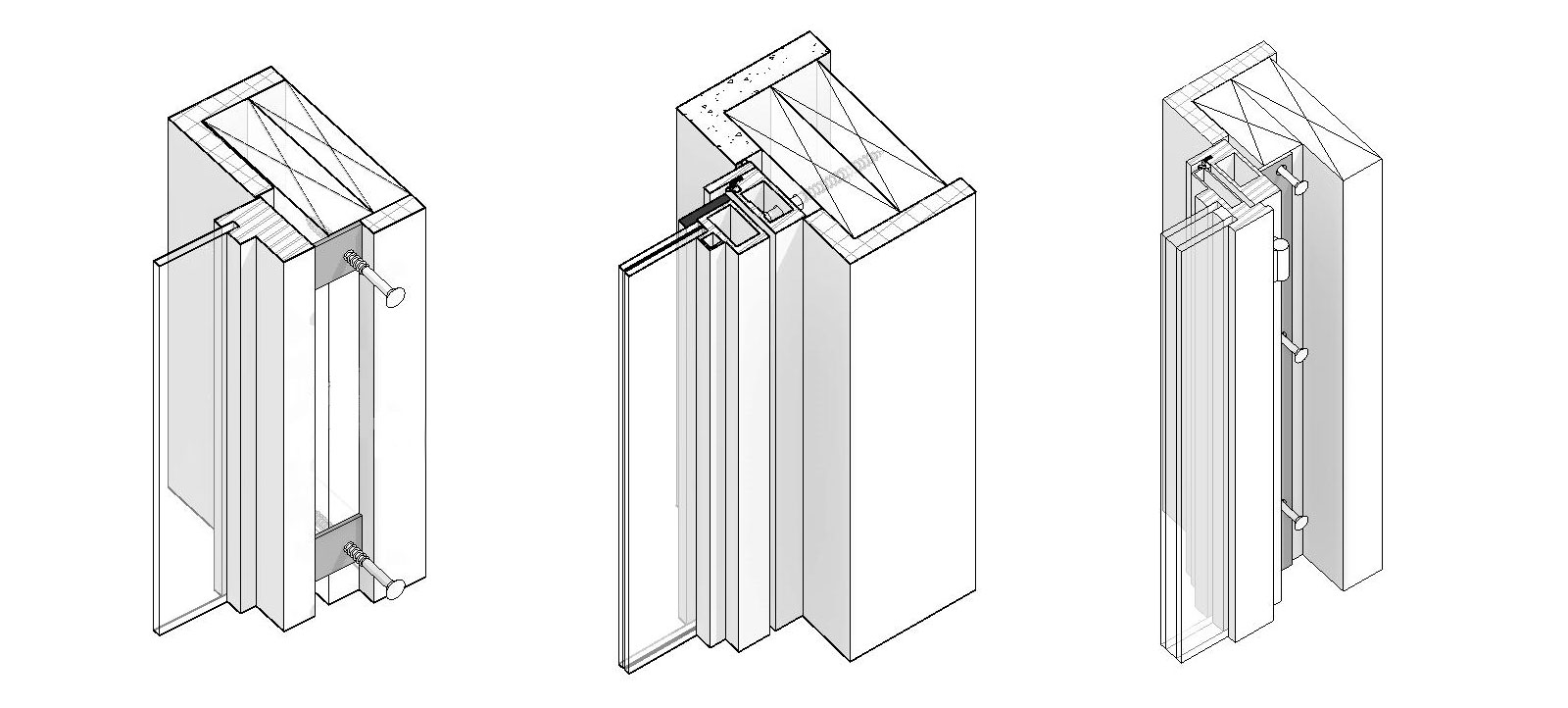

Dutch Door

French Door

- SLIDING

Multi-Slider

Pocket Multi-Slider

Lift And Slide

- BIFOLD

Outswing Fold

Center Fold

Inswing Fold

- PIVOT

Pivot Door

Pivot Window

- SERIES

- ABOUT

- FINISHES

- PROFESSIONALS

- FIND A DEALER

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

CONTACT US

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

- PRODUCTS

OUR PRODUCTS

- WINDOWS

Fixed Window

Casement Window

Awning Window

Bi-Fold Window

Sliding Window

Pivot Window

- SWING

Single Swing

Dutch Door

French Door

- SLIDING

Multi-Slider

Pocket Multi-Slider

Lift And Slide

- BIFOLD

Outswing Fold

Center Fold

Inswing Fold

- PIVOT

Pivot Door

Pivot Window

- SERIES

- ABOUT

- FINISHES

- PROFESSIONALS

- FIND A DEALER

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

CONTACT US

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

- PRODUCTS

OUR PRODUCTS

- WINDOWS

Fixed Window

Casement Window

Awning Window

Bi-Fold Window

Sliding Window

Pivot Window

- SWING

Single Swing

Dutch Door

French Door

- SLIDING

Multi-Slider

Pocket Multi-Slider

Lift And Slide

- BIFOLD

Outswing Fold

Center Fold

Inswing Fold

- PIVOT

Pivot Door

Pivot Window

- SERIES

- ABOUT

- FINISHES

- PROFESSIONALS

- FIND A DEALER

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

CONTACT US

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA

OUR HEADQUATERS & MANUFACTURING FACILITY IN VISTA CALIFORNIA